Catalogue Search | MBRL

Search Results Heading

Explore the vast range of titles available.

MBRLSearchResults

-

DisciplineDiscipline

-

Is Peer ReviewedIs Peer Reviewed

-

Series TitleSeries Title

-

Reading LevelReading Level

-

YearFrom:-To:

-

More FiltersMore FiltersContent TypeItem TypeIs Full-Text AvailableSubjectCountry Of PublicationPublisherSourceTarget AudienceDonorLanguagePlace of PublicationContributorsLocation

Done

Filters

Reset

41

result(s) for

"Beaumont, Marco"

Sort by:

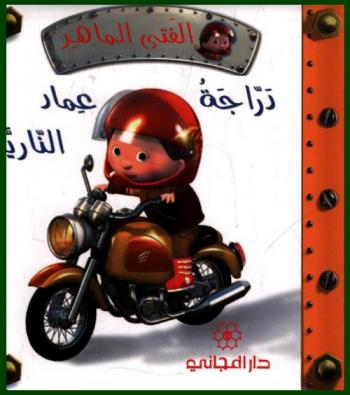

دراجة عماد النارية

by

Beaumont, Emilie, مؤلف

,

Bélineau, Nathalie, صاحب فكرة

,

Nesme, Alexis, 1974- رسام

in

القصص الفرنسية للأطفال قرن 21

,

الأدب الفرنسي قرن 21

2015

تتناول قصة (دراجة عماد النارية) والذي قامه بتأليفه (إميلي بومون) (تعريب زينا شلهوب عون) في حوالي (14) صفحة من القطع المتوسط موضوع (القصص الفرنسية للأطفال) مستعرضا المحتويات التالية : قصة يستطيع الولد من خلالها أن يلعب دور البطل مطلقا العنان لمخيلته وهي تعمل على تدريب الأطفال على الاعتماد على النفس.

Porous Silk Fibroin/Cellulose Hydrogels for Bone Tissue Engineering via a Novel Combined Process Based on Sequential Regeneration and Porogen Leaching

by

Rosenau, Thomas

,

Tamada, Yasushi

,

Burger, Dennis

in

alkaline phosphatase

,

Animals

,

bicontinuous composite

2020

Scaffolds used for bone tissue engineering need to have a variety of features to accommodate bone cells. The scaffold should mimic natural bone, it should have appropriate mechanical strength, support cell differentiation to the osteogenic lineage, and offer adequate porosity to allow vascularization and bone in-growth. In this work, we aim at developing a new process to fabricate such materials by creating a porous composite material made of silk fibroin and cellulose as a suitable scaffold of bone tissue engineering. Silk fibroin and cellulose are both dissolved together in N,N-dimethylacetamide/LiCl and molded to a porous structure using NaCl powder. The hydrogels are prepared by a sequential regeneration process: cellulose is solidified by water vapor treatment, while the remaining silk fibroin in the hydrogel is insolubilized by methanol, which leads to a cellulose framework structure embedded in a silk fibroin matrix. Finally, the hydrogels are soaked in water to dissolve the NaCl for making a porous structure. The cellulose composition results in improving the mechanical properties for the hydrogels in comparison to the silk fibroin control material. The pore size and porosity are estimated at around 350 µm and 70%, respectively. The hydrogels support the differentiation of MC3T3 cells to osteoblasts and are expected to be a good scaffold for bone tissue engineering.

Journal Article

Unique reactivity of nanoporous cellulosic materials mediated by surface-confined water

2021

The remarkable efficiency of chemical reactions is the result of biological evolution, often involving confined water. Meanwhile, developments of bio-inspired systems, which exploit the potential of such water, have been so far rather complex and cumbersome. Here we show that surface-confined water, inherently present in widely abundant and renewable cellulosic fibres can be utilised as nanomedium to endow a singular chemical reactivity. Compared to surface acetylation in the dry state, confined water increases the reaction rate and efficiency by 8 times and 30%, respectively. Moreover, confined water enables control over chemical accessibility of selected hydroxyl groups through the extent of hydration, allowing regioselective reactions, a major challenge in cellulose modification. The reactions mediated by surface-confined water are sustainable and largely outperform those occurring in organic solvents in terms of efficiency and environmental compatibility. Our results demonstrate the unexploited potential of water bound to cellulosic nanostructures in surface esterifications, which can be extended to a wide range of other nanoporous polymeric structures and reactions.

The efficiency of chemical reactions in biological systems is often connected to the properties of confined water, but the developments and applications of artificial mimicking systems are impeded by the complexity of the biological systems. Here, the authors show how surface bound water in nanoporous cellulosic fibers can increase the reaction rate of surface acetylation reactions and enable regioselectivity of the reaction

Journal Article

A General Aqueous Silanization Protocol to Introduce Vinyl, Mercapto or Azido Functionalities onto Cellulose Fibers and Nanocelluloses

by

Gindl-Altmutter, Wolfgang

,

Rosenau, Thomas

,

Opietnik, Martina

in

aqueous silanization

,

Catalysis

,

Cellulose - chemistry

2018

The effective and straight-forward modification of nanostructured celluloses under aqueous conditions or as “never-dried” materials is challenging. We report a silanization protocol in water using catalytic amounts of hydrogen chloride and then sodium hydroxide in a two-step protocol. The acidic step hydrolyzes the alkoxysilane to obtain water-soluble silanols and the subsequent addition of catalytic amounts of NaOH induces a covalent reaction between cellulose surficial hydroxyl groups and the respective silanols. The developed protocol enables the incorporation of vinyl, thiol, and azido groups onto cellulose fibers and cellulose nanofibrils. In contrast to conventional methods, no curing or solvent-exchange is necessary, thereby the functionalized celluloses remain never-dried, and no agglomeration or hornification occurs in the process. The successful modification was proven by solid state NMR, ATR-IR, and EDX spectroscopy. In addition, the covalent nature of this bonding was shown by gel permeation chromatography of polyethylene glycol grafted nanofibrils. By varying the amount of silane agents or the reaction time, the silane loading could be tuned up to an amount of 1.2 mmol/g. Multifunctional materials were obtained either by prior carboxymethylation and subsequent silanization; or by simultaneously incorporating both vinyl and azido groups. The protocol reported here is an easy, general, and straight-forward avenue for introduction of anchor groups onto the surface of never-dried celluloses, ready for click chemistry post-modification, to obtain multifunctional cellulose substrates for high-value applications.

Journal Article

Surface properties and porosity of highly porous, nanostructured cellulose II particles

by

Kondor, Anett

,

Mitterer, Claudia

,

Opietnik, Martina

in

Aerogels

,

Bioorganic Chemistry

,

Cellulose

2017

Recently, a new member of the nanocellulose family was introduced, a cellulose II gel consisting of nanostructured and spherical particles. In this study, we compared two different drying techniques to obtain highly porous powders from this gel with preserved meso- and macroporous nanostructure: first, freeze-drying after solvent exchange to

t

BuOH and second, supercritical drying of the respective EtOH alcogel. The approaches yielded aerogel powders with surface areas of 298 and 423 m

2

/g, respectively. Both powders are amphiphilic and possess energetically heterogeneous surfaces with dominating dispersive term of the surface energy in the range of 50–52 mJ/m

2

, as determined by a combination of physicochemical surface characterization techniques, such as iGC, BET and SEM. Despite the lower surface area, the cheaper and more widespread method, freeze-drying, yields a more polar and reactive cryogel.

Journal Article

Facile Preparation of Mechanically Robust and Functional Silica/Cellulose Nanofiber Gels Reinforced with Soluble Polysaccharides

by

Jahn, Elisabeth

,

Potthast, Antje

,

Gindl-Altmutter, Wolfgang

in

aerogels

,

Ammonia

,

aqueous process

2022

Nanoporous silica gels feature extremely large specific surface areas and high porosities and are ideal candidates for adsorption-related processes, although they are commonly rather fragile. To overcome this obstacle, we developed a novel, completely solvent-free process to prepare mechanically robust CNF-reinforced silica nanocomposites via the incorporation of methylcellulose and starch. Significantly, the addition of starch was very promising and substantially increased the compressive strength while preserving the specific surface area of the gels. Moreover, different silanes were added to the sol/gel process to introduce in situ functionality to the CNF/silica hydrogels. Thereby, CNF/silica hydrogels bearing carboxyl groups and thiol groups were produced and tested as adsorber materials for heavy metals and dyes. The developed solvent-free sol/gel process yielded shapable 3D CNF/silica hydrogels with high mechanical strength; moreover, the introduction of chemical functionalities further widens the application scope of such materials.

Journal Article

Drying of a cellulose II gel: effect of physical modification and redispersibility in water

by

Rosenau, Thomas

,

Opietnik, Martina

,

König, Jakob

in

Additives

,

ammonium bicarbonate

,

Bicarbonates

2017

The agglomeration of cellulosic materials upon drying, often called hornification, causes a reduction of water retention, among other undesired effects. It is one of the main issues in industrial cellulose processing, especially with regard to nanocelluloses. As a consequence, high transportation and storage costs arise since nanocelluloses need to remain in aqueous suspensions unless trade-offs in reactivity, redispersibility and surface properties are accepted. In this study, different drying strategies for TENCEL

®

gel, a nanostructured gel derived from the Lyocell process consisting of spherical particles, are compared and evaluated. First, freeze-drying with consideration of the influence of freezing temperature and the use of

tert

-butanol as cryo-protectant, and second, simple oven-drying at 60 °C. Surprisingly, oven-dried xerogels showed higher water retention values and also better colloidal stability than the cryogels. This is in stark contrast to cellulose nanofibrils for which freeze-drying has been shown to be significantly superior to oven drying in terms of redispersibility. For the TENCEL

®

gel, oven-drying was thus selected and the influence of additives on the redispersibility of the cellulose II gel was studied by means of the common water retention value, particle size, colloidal stability, appearance of the redispersed gel and viscosity. The addition of the polysaccharides carboxymethyl cellulose or xanthan showed the most promising results with regard to redispersibility. Also sucrose and ammonium bicarbonate provided higher colloidal stabilities than that of the untreated TENCEL

®

gel. The redispersibility of the cellulose II xerogels could thus be significantly improved by simple and cost-efficient mixing with additives prior to drying.

Journal Article

Immobilized cellulose nanospheres enable rapid antigen detection in lateral flow immunoassays

2023

Rapid diagnostic systems are essential in controlling the spread of viral pathogens and efficient patient management. The available technologies for low-cost viral antigen testing have several limitations, including a lack of accuracy and sensitivity. Here, we introduce a platform based on cellulose II nanoparticles (oppositely charged NPan and NPcat) for effective control of surface protein interactions, leading to rapid and sensitive antigen tests. Passivation against non-specific adsorption and augmented immobilization of sensing antibodies is achieved by adjusting the electrostatic charge of the nanoparticles. The interactions affecting the performance of the system are investigated by microgravimetry and confocal imaging. As a proof-of-concept test, SARS-CoV-2 nucleocapsid sensing was carried out by using saliva-wicking by channels that were stencil-printed on paper. We conclude that inkjet-printed NPcat elicits strong optical signals, visible after a few minutes, opening the opportunity for cost-effective and rapid diagnostic.

Journal Article

Manufacturing heat-damaged papers as model materials for evaluating conservation methods

2022

Direct fire, indirect heat, and extinguishing water cause great damage to cultural assets upon a fire disaster in a library or archive. Conservation and restoration of heat-damaged papers are particularly challenging due to the complexity and severity of the damage. Since valuable originals obviously cannot be used for the development of treatment methods and only to a limited extent for the analysis of the damage, it is necessary to produce model paper materials that have a high degree of similarity to fire-damaged papers, which was addressed in the present study. Three different heating methods were tested to produce model papers of different heating levels. Their altered optical, structural, and chemical properties were analyzed and compared with the results of original fire-damaged samples. The study points out pathways to enable the production of comparable sample materials. Heating between hot plates or in an oven produces papers that have properties quite similar to the originals in terms of surface area, paper structure, cellulose integrity, and interactions with water. Stack heating in the oven has proven to be a particularly effective manufacturing method for larger quantities of model papers.

Journal Article