Catalogue Search | MBRL

Search Results Heading

Explore the vast range of titles available.

MBRLSearchResults

-

DisciplineDiscipline

-

Is Peer ReviewedIs Peer Reviewed

-

Item TypeItem Type

-

Is Full-Text AvailableIs Full-Text Available

-

YearFrom:-To:

-

More FiltersMore FiltersSubjectPublisherSourceLanguagePlace of PublicationContributors

Done

Filters

Reset

101,078

result(s) for

"Meat Processing."

Sort by:

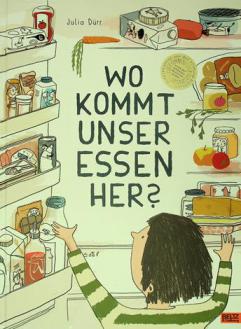

Wo kommt unser Essen her?

\"Woher kommen eigentlich die Lebensmittel, die auf unserem Tisch landen? Dieses Sachbilderbuch zeigt die verschiedenen Produktionsabläufe in kleinen und großen Betrieben: den Weg der Milch auf einem Bauernhof und in einem Milchbetrieb oder wie das Brot in der Backstube und wie es in der Backfabrik entsteht, Fischfang und Fischzucht. Wie und wo Tomaten oder Äpfel wachsen, was passiert, bevor die Wurst in die Pelle kommt - und was das alles mit dem Klima zu tun hat, erklären die detailreichen, großformatigen Bilder und die leicht verständlichen Texte.\" -- Various websites

Characteristics of SARS-CoV-2 Transmission among Meat Processing Workers in Nebraska, USA, and Effectiveness of Risk Mitigation Measures

2021

The coronavirus disease (COVID-19) pandemic has severely impacted the meat processing industry in the United States. We sought to detail demographics and outcomes of severe acute respiratory syndrome coronavirus 2 infections among workers in Nebraska meat processing facilities and determine the effects of initiating universal mask policies and installing physical barriers at 13 meat processing facilities. During April 1-July 31, 2020, COVID-19 was diagnosed in 5,002 Nebraska meat processing workers (attack rate 19%). After initiating both universal masking and physical barrier interventions, 8/13 facilities showed a statistically significant reduction in COVID-19 incidence in <10 days. Characteristics and incidence of confirmed cases aligned with many nationwide trends becoming apparent during this pandemic: specifically, high attack rates among meat processing industry workers, disproportionately high risk of adverse outcomes among ethnic and racial minority groups and men, and effectiveness of using multiple prevention and control interventions to reduce disease transmission.

Journal Article

Biofilms and Meat Safety: A Mini-Review

2019

Biofilms are surface-attached microbial communities with distinct properties, which have a tremendous impact on public health and food safety. In the meat industry, biofilms remain a serious concern because many foodborne pathogens can form biofilms in areas at meat plants that are difficult to sanitize properly, and biofilm cells are more tolerant to sanitization than their planktonic counterparts. Furthermore, nearly all biofilms in commercial environments consist of multiple species of microorganisms, and the complex interactions within the community significantly influence the architecture, activity, and sanitizer tolerance of the biofilm society. This review focuses on the effect of microbial coexistence on mixed biofilm formation with foodborne pathogens of major concern in the fresh meat industry and their resultant sanitizer tolerance. The factors that would affect biofilm cell transfer from contact surfaces to meat products, one of the most common transmission routes that could lead to product contamination, are discussed as well. Available results from recent studies relevant to the meat industry, implying the potential role of bacterial persistence and biofilm formation in meat contamination, are reviewed in response to the pressing need to understand the mechanisms that cause \"high event period\" contamination at commercial meat processing plants. A better understanding of these events would help the industry to enhance strategies to prevent contamination and improve meat safety.

Journal Article

SARS‐CoV‐2 outbreak investigation in a German meat processing plant

by

Indenbirken, Daniela

,

Günther, Thomas

,

Brinkmann, Melanie M

in

aerosol transmission

,

Aerosols

,

COVID-19 - diagnosis

2020

We describe a multifactorial investigation of a SARS‐CoV‐2 outbreak in a large meat processing complex in Germany. Infection event timing, spatial, climate and ventilation conditions in the processing plant, sharing of living quarters and transport, and viral genome sequences were analyzed. Our results suggest that a single index case transmitted SARS‐CoV‐2 to co‐workers over distances of more than 8 m, within a confined work area in which air is constantly recirculated and cooled. Viral genome sequencing shows that all cases share a set of mutations representing a novel sub‐branch in the SARS‐CoV‐2 C20 clade. We identified the same set of mutations in samples collected in the time period between this initial infection cluster and a subsequent outbreak within the same factory, with the largest number of confirmed SARS‐CoV‐2 cases in a German meat processing facility reported so far. Our results indicate climate conditions, fresh air exchange rates, and airflow as factors that can promote efficient spread of SARS‐CoV‐2 via long distances and provide insights into possible requirements for pandemic mitigation strategies in industrial workplace settings.

Synopsis

There has been considerable debate about the factors contributing to SARS‐CoV‐2 outbreaks in food processing facilities around the world. This multifactorial investigation of an outbreak in a German meat processing plant shows that transmission occurred in a confined working area over long distances.

Analysis of infection event timing, spatial, climate and ventilation conditions, living quarters and transport, and viral genome sequences suggests a super spreading event that originated from a single employee.

Infections among workers over a distance of 8 m from the index case suggest aerosol transmission of SARS‐CoV-2.

The facilities’ environmental conditions such as low temperature, low air exchange rates, and constant air recirculation, together with relatively close distance between workers and demanding physical work, may have promoted efficient aerosol transmission.

In contrast to work‐related exposure, shared apartments, bedrooms, or carpools appear not to have played a major role in the initial outbreak.

Viral genome sequencing reveals a characteristic set of mutations that was also observed in samples collected during a later, much larger outbreak occurring in the same processing plant.

Graphical Abstract

There has been considerable debate about the factors contributing to SARS‐CoV‐2 outbreaks in food processing facilities around the world. This multifactorial investigation of an outbreak in a German meat processing plant shows that transmission occurred in a confined working area over long distances.

Journal Article

Safely and autonomously cutting meat with a collaborative robot arm

2024

Labor shortages in the United States are impacting a number of industries including the meat processing sector. Collaborative technologies that work alongside humans while increasing production abilities may support the industry by enhancing automation and improving job quality. However, existing automation technologies used in the meat industry have limited collaboration potential, low flexibility, and high cost. The objective of this work was to explore the use of a robot arm to collaboratively work alongside a human and complete tasks performed in a meat processing facility. Toward this objective, we demonstrated proof-of-concept approaches to ensure human safety while exploring the capacity of the robot arm to perform example meat processing tasks. In support of human safety, we developed a knife instrumentation system to detect when the cutting implement comes into contact with meat within the collaborative space. To demonstrate the capability of the system to flexibly conduct a variety of basic meat processing tasks, we developed vision and control protocols to execute slicing, trimming, and cubing of pork loins. We also collected a subjective evaluation of the actions from experts within the U.S. meat processing industry. On average the experts rated the robot’s performance as adequate. Moreover, the experts generally preferred the cuts performed in collaboration with a human worker to cuts completed autonomously, highlighting the benefits of robotic technologies that assist human workers rather than replace them. Video demonstrations of our proposed framework can be found here:

https://youtu.be/56mdHjjYMVc

.

Journal Article

Application of Plant Proteases in Meat Tenderization: Recent Trends and Future Prospects

2023

Papain, bromelain, and ficin are commonly used plant proteases used for meat tenderization. Other plant proteases explored for meat tenderization are actinidin, zingibain, and cucumin. The application of plant crude extracts or powders containing higher levels of compounds exerting tenderizing effects is also gaining popularity due to lower cost, improved sensory attributes of meat, and the presence of bioactive compounds exerting additional benefits in addition to tenderization, such as antioxidants and antimicrobial effects. The uncontrolled plant protease action could cause excessive tenderization (mushy texture) and poor quality due to an indiscriminate breakdown of proteins. The higher cost of separation and the purification of enzymes, unstable structure, and poor stability of these enzymes due to autolysis are some major challenges faced by the food industry. The meat industry is targeting the recycling of enzymes and improving their stability and shelf-life by immobilization, encapsulation, protein engineering, medium engineering, and stabilization during tenderization. The present review critically analyzed recent trends and the prospects of the application of plant proteases in meat tenderization.

Journal Article

Investigation of superspreading COVID-19 outbreak events in meat and poultry processing plants in Germany: A cross-sectional study

by

Pokora, Roman

,

Kutschbach, Susan

,

Hecht, Juergen

in

Biology and Life Sciences

,

Catering

,

Coronaviruses

2021

Since May 2020, several COVID-19 outbreaks have occurred in the German meat industry despite various protective measures, and temperature and ventilation conditions were considered as possible high-risk factors. This cross-sectional study examined meat and poultry plants to assess possible risk factors. Companies completed a self-administered questionnaire on the work environment and protective measures taken to prevent SARS-CoV-2 infection. Multivariable logistic regression analysis adjusted for the possibility to distance at least 1.5 meters, break rules, and employment status was performed to identify risk factors associated with COVID-19 cases. Twenty-two meat and poultry plants with 19,072 employees participated. The prevalence of COVID-19 in the seven plants with more than 10 cases was 12.1% and was highest in the deboning and meat cutting area with 16.1%. A subsample analysis where information on maximal ventilation rate per employee was available revealed an association with the ventilation rate (adjusted odds ratio (AOR) 0.996, 95% CI 0.993–0.999). When including temperature as an interaction term in the working area, the association with the ventilation rate did not change. When room temperatures increased, the chance of testing positive for COVID-19 (AOR 0.90 95% CI 0.82–0.99) decreased, and the chance for testing positive for COVID-19for the interaction term (AOR 1.001, 95% CI 1.000–1.003) increased. Employees who work where a minimum distance of less than 1.5 m between workers was the norm had a higher chance of testing positive (AOR 3.61; 95% CI 2.83–4.6). Our results further indicate that climate conditions and low outdoor air flow are factors that can promote the spread of SARS-CoV-2 aerosols. A possible requirement for pandemic mitigation strategies in industrial workplace settings is to increase the ventilation rate.

Journal Article

Addressing Clean Label Trends in Commercial Meat Processing: Strategies, Challenges and Insights from Consumer Perspectives

2023

Background: The concept of a clean label is difficult to define, even in common language, as the interpretation of what a “clean” food is differs from one person to another and from one organisation to another. The lack of a unique definition and regulations of what the term “clean” means, along with the growing consumer demand for more “natural” and healthier foods, is posing new challenges for manufacturers and ingredient producers. The meat industry, in particular, has been affected by this new movement owing to negative attitudes and feelings consumers associate with consuming processed meat products. Scope and approach: The review scope is to describe attributes and associations around the “clean” label term by analysing the most recent ingredients, additives and processing methods currently available for meat manufacturers. Their application in meat, plant-based alternatives and hybrid meat/plant products, current limitations and challenges presented in consumer perception, safety and potential impacts on product quality are also presented. Key findings and conclusions: The availability of a growing number of “clean” label ingredients provides a new suite of approaches that are available for application by meat processors to help overcome some of the negative connotations associated with processed meat products and also support plant-based meat alternatives and hybrids.

Journal Article

Clean Label Alternatives in Meat Products

by

Pintado, Tatiana

,

Stratakos, Alexandros C.

,

Ekonomou, Sotirios I.

in

Additives

,

anti-infective agents

,

Antiinfectives and antibacterials

2021

Food authorities have not yet provided a definition for the term “clean label”. However, food producers and consumers frequently use this terminology for food products with few and recognisable ingredients. The meat industry faces important challenges in the development of clean-label meat products, as these contain an important number of functional additives. Nitrites are an essential additive that acts as an antimicrobial and antioxidant in several meat products, making it difficult to find a clean-label alternative with all functionalities. Another important additive not complying with the clean-label requirements are phosphates. Phosphates are essential for the correct development of texture and sensory properties in several meat products. In this review, we address the potential clean-label alternatives to the most common additives in meat products, including antimicrobials, antioxidants, texturisers and colours. Some novel technologies applied for the development of clean label meat products are also covered.

Journal Article

Role of Enzymatic Reactions in Meat Processing and Use of Emerging Technologies for Process Intensification

2023

Meat processing involves different transformations in the animal muscle after slaughtering, which results in changes in tenderness, aroma and colour, determining the quality of the final meat product. Enzymatic glycolysis, proteolysis and lipolysis play a key role in the conversion of muscle into meat. The accurate control of enzymatic reactions in meat muscle is complicated due to the numerous influential factors, as well as its low reaction rate. Moreover, exogenous enzymes are also used in the meat industry to produce restructured products (transglutaminase), to obtain bioactive peptides (peptides with antioxidant, antihypertensive and gastrointestinal activity) and to promote meat tenderization (papain, bromelain, ficin, zingibain, cucumisin and actinidin). Emerging technologies, such as ultrasound (US), pulsed electric fields (PEF), moderate electric fields (MEF), high-pressure processing (HPP) or supercritical CO2 (SC-CO2), have been used to intensify enzymatic reactions in different food applications. This review aims to provide an overview of the enzymatic reactions taking place during the processing of meat products, how they could be intensified by using emerging technologies and envisage potential applications.

Journal Article