Catalogue Search | MBRL

Search Results Heading

Explore the vast range of titles available.

MBRLSearchResults

-

DisciplineDiscipline

-

Is Peer ReviewedIs Peer Reviewed

-

Series TitleSeries Title

-

Reading LevelReading Level

-

YearFrom:-To:

-

More FiltersMore FiltersContent TypeItem TypeIs Full-Text AvailableSubjectCountry Of PublicationPublisherSourceTarget AudienceDonorLanguagePlace of PublicationContributorsLocation

Done

Filters

Reset

50,848

result(s) for

"Steam"

Sort by:

Parametric Analysis and Optimization of a Dual‐Fuel‐Fired Boiler for Power Generation Using the Taguchi Design Approach

by

Oyedepo, Sunday O.

,

Shopeju, Oyekunle O.

,

Ajala, Olajide O.

in

Air flow

,

Air temperature

,

Alternative energy sources

2025

Increased energy supply reliability, environmental sustainability, more competitive businesses, and improved standard of living are all made possible by more efficient energy conversion processes. In view of this, the present study aims at analysis and optimization of the operational parameters of a dual‐fuel‐fired boiler using Taguchi design method to enhance boiler thermal efficiency and throughput for sustainable power generation. The L27 orthogonal array (OA) was employed with 27 experimental runs to assess the influence of the four identified design parameters: economizer outlet water temperature (EOWT), total airflow (TAF), gas air heater outlet temperature (GAHOT), and feed water temperature (FWT) on the boiler main steam flow (BMSF). Box–Behnken factorial design from Minitab 18 was used to analyze the effects of the design factors and runs on the response parameter. Results of the study reveal that the quadratic regression model developed with the Taguchi design predicted the BMSF at 95.5% confidence level. The optimal signal‐to‐noise (S/N) ratio of 56.57 and maximum BMSE of 674 T/h were achieved at the optimal design parameters of 257°C of EOWT, 64% of TAF, 237°C of GAHOT and FWT of 210°C at the boiler feed drum. The adequacy and degree of fitness of the quadratic models developed were determined using the coefficient of determination ( R 2 ), adjusted and predicted R 2 , and adequate precision. The coefficient of determination R 2 values for the BMSF model and S/N ratio model are 0.9995 and 0.9990, respectively. The R 2 values show that the developed models have a good fit and ability to predict BMSF and S/N ratio accurately. In addition, adjusted R 2 (BMSF model: 0.9990; S/N ratio model: 0.9981) and predicted R 2 (BMSF model: 0.9956; S/N ratio: 0.9955) values are in reasonable agreement as their difference is less than 0.2. Conclusively, this study shows that the most influential factor on BMSF is the EOWT with a percentage contributing ratio of 38%; this is followed by FWT with 36%. From the prediction analysis and with the optimized factors, the efficiency of the existing steam turbine power plant of 33% could be increased to 55%.

Journal Article

The mighty steam engine

by

Ng, Yvonne, author

,

Smythe, Richard, 1986- illustrator

in

Steam engines Juvenile fiction.

,

Railroad trains Juvenile fiction.

,

Stories in rhyme.

2019

Illustrations and a cumulative rhyme, in the style of \"The House that Jack Built,\" introduce the inner workings of a steam engine and how it powers a train.

Utilizing a pressure-based CFD solver for modelling wet steam flow in low-pressure turbine stages: a predictive approach to assessing flow losses

by

Dykas, Slawomir

,

Shabani, Sima

,

Smolka, Krystian

in

Energy costs

,

Low pressure

,

Steam electric power generation

2024

This research focuses on addressing a critical challenge in steam turbine operation, specifically condensation losses within the Low-Pressure (LP) section. Such losses have a significant impact on energy efficiency and operational costs in industries like power generation and manufacturing. The objective of this research is to predict condensation losses in the LP part of steam turbines. The simulation of the two-phase flow of wet steam is performed in the ANSYS CFX software. The geometry studied in this research is the actual geometry of the last stage of a steam turbine, which is modeled in three dimensions. The complexities of modeling three-dimensional flows, as well as providing relationships that can be used to calculate losses that can be generalized and used in different conditions, are distinctive features of this research.

Journal Article

Digger man

by

Zimmerman, Andrea Griffing, author

,

Clemesha, David, illustrator

in

Steam shovels Juvenile fiction.

,

Excavating machinery Juvenile fiction.

,

Brothers Juvenile fiction.

2011

A young boy imagines how he will use his digger to make a park where he and his little brother can play.

Steam turbine power prediction based on encode-decoder framework guided by the condenser vacuum degree

by

Yue, Junfeng

,

Si, Jiasheng

,

He, Pengfei

in

Artificial intelligence

,

Artificial neural networks

,

Biology and Life Sciences

2022

The steam turbine is one of the major pieces of equipment in thermal power plants. It is crucial to predict its output accurately. However, because of its complex coupling relationships with other equipment, it is still a challenging task. Previous methods mainly focus on the operation of the steam turbine individually while ignoring the coupling relationship with the condenser, which we believe is crucial for the prediction. Therefore, in this paper, to explore the coupling relationship between steam turbine and condenser, we propose a novel approach for steam turbine power prediction based on the encode-decoder framework guided by the condenser vacuum degree (CVD-EDF). In specific, the historical information within condenser operation conditions data is encoded using a long-short term memory network. Moreover, a connection module consisting of an attention mechanism and a convolutional neural network is incorporated to capture the local and global information in the encoder. The steam turbine power is predicted based on all the information. In this way, the coupling relationship between the condenser and the steam turbine is fully explored. Abundant experiments are conducted on real data from the power plant. The experimental results show that our proposed CVD-EDF achieves great improvements over several competitive methods. our method improves by 32.2% and 37.0% in terms of RMSE and MAE by comparing the LSTM at one-minute intervals.

Journal Article

The great railway show ; Off to the races!

by

Stubbs, Tommy, illustrator

,

Allcroft, Britt, creator

,

HIT Entertainment

in

Thomas, the Tank Engine (Fictitious character) Juvenile fiction.

,

Thomas, the Tank Engine (Fictitious character) Fiction.

,

Thomas, the Tank Engine (Fictitious character)

2016

Based on the upcoming Thomas & Friends movie, this paperback storybook features two stories about Thomas and his railroad friends.

The search for an appropriate condensation model to simulate wet steam transonic flows

by

Lakzian, Esmail

,

Ramezani, Mostafa

,

Salmani, Fahime

in

Boundary conditions

,

Condensation

,

Convergent-divergent nozzles

2023

Purpose

The purpose of this study is to model steam condensing flows through steam turbine blades and find the most suitable condensation model to predict the condensation phenomenon.

Design/methodology/approach

To find the most suitable condensation model, five nucleation equations and four droplet growth equations are combined, and 20 cases are considered for modelling the wet steam flow through steam turbine blades. Finally, by the comparison between the numerical results and experiments, the most suitable case is proposed. To find out whether the proposed case is also valid for other boundary conditions and geometries, it is used to simulate wet steam flows in de Laval nozzles.

Findings

The results indicate that among all the cases, combining the Hale nucleation equation with the Gyarmathy droplet growth equation results in the smallest error in the simulation of wet steam flows through steam turbine blades. Compared with experimental data, the proposed model’s relative error for the static pressure distribution on the blade suction and pressure sides is 2.7% and 2.3%, respectively, and for the liquid droplet radius distribution it totals to 1%. This case is also reliable for simulating condensing steam flows in de Laval nozzles.

Originality/value

The selection of an appropriate condensation model plays a vital role in the simulation of wet steam flows. Considering that the results of numerical studies on condensation models in recent years have not been completely consistent with the experiments and that there are still uncertainties in this field, further studies aiming to improve condensation models are of particular importance. As condensation models play an important role in simulating the condensation phenomenon, this research can help other researchers to better understand the purpose and importance of choosing a suitable condensation model in improving the results. This study is a significant step to improve the existing condensation models and it can help other researchers to gain a revealing insight into choosing an appropriate condensation model for their simulations.

Journal Article

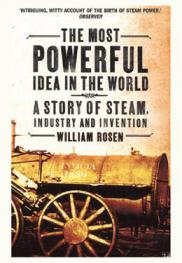

The most powerful idea in the world : a story of steam, industry and invention

States that the most important invention of the Industrial Revolution was invention itself. This book offers an account of how inventors first came to own and profit from their ideas-and how invention itself springs forth from logic and imagination. It describes the experiments and accomplishments that led to this revolution.

Modern Coal-Fired Power Units for Ultra-Supercritical Steam Conditions (Review)

by

Somova, E. V.

,

Tumanovskii, A. G.

,

Tugov, A. N.

in

Alternative energy sources

,

Coal-fired power plants

,

Combined-Cycle Power Plants

2023

The share of coal generation in the global electricity production remains stable and prevails over other primary energy sources. A decrease in the coal-fired power generation in some EU countries and the United States is balanced by its stable growth in Asia (China, India, Indonesia, South Korea) and Africa (South Africa). In 2021, global coal generation increased by 9% to a new all-time high of 10 337 TW h. According to the forecast of the International Energy Agency (IEA), coal consumption in the power industry will remain at about the same level in the coming years, mainly due to the countries of Southeast Asia. Furthermore, at the UN climate conference held in Glasgow in November 2021, the official phasedown of all coal-fired generation was not set forth. Globally, 247.7 GW of ultra-supercritical (USC) power units, which are characterized by high efficiency and minimal environmental impact, have been commissioned during the past decade. Steam conditions of 32.58 MPa/610/630/623°C (for live, reheat, and, secondary reheat steam, respectively) and an efficiency of 48.92% were reached in a 1350-MW power unit at the Shenergy Pingshan II thermal power plant (TPP) (China). A review of the USC technology evolution in the world and basic solutions for boilers, flue gas treatment system, and steam turbines are presented. In Russia there are no plans to construct large coal-fired power units in the coming years. Development of a gas-and-oil fired power unit for ultrasupercritical steam conditions with elaborating the thermal cycle key equipment components—primarily the turbine and steam lines—can serve as a pilot project for mastering the USC technology.

Journal Article